Aluminium Gate Automation creates a new piece of machinery from a number of components.

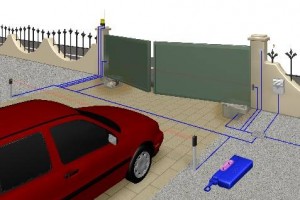

This means that any gate automation professional has to CE mark their machinery once the gate motors, gate automation safety devices, control system, and any additional items such as access control code entry, voice or video intercoms, are installed and operational.

There is the potential for harm to anyone from a badly conceived or an incorrectly installed gate automation system so it’s imperative that any installer carries out a full hazard assessment when designing an aluminium gate automation system to meet a client’s requirements.

Equipment for aluminium gate automation is often sourced from mainland Europe as many leaders in this industry come from countries such as Italy and Germany. Traditionally, Italians and residents of many other European countries see guarding the perimeter of their property equally as important as locking their house doors and windows. Consequently, gates have to be shut when not in use and open automatically as required.

In the UK, we’re a few years behind in terms of the popularity of automatic electric gates. To some, they are seen as a bit snobbish and elite. However, the principle is very sound. If you have gates, you have to open and close them by hand or leave them open unless you add a system that will open and close your gates automatically.